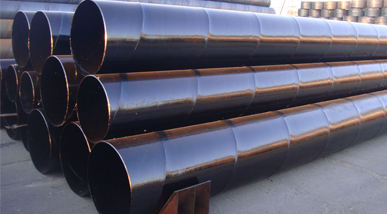

SAW Spiral Welded

| SPİRAL ÇELİK BORU ÜRETİM ARALIĞI TABLOSU | ||||||||||||||||||

| SPIRALLY WELDED STEEL PIPE PRODUCTION RANGE TABLE | ||||||||||||||||||

|

Nominal Çap Nominal Diametler

inc. mm |

Standart Dış Çap Standart O.D

mm. |

Et Kalınlıkları/W.T.( mm/inch) | ||||||||||||||||

|

4.0 0.157 |

4.5 0.177 |

5.0 0.196 |

5.6 0.220 |

6.3 0.248 |

7.1 0.279 |

8.0 0.314 |

8.8 0.344 |

10.0 0.393 |

11.0 0.433 |

12.5 0.492 |

14.2 0.559 |

16.0 0.629 |

17.5 0.688 |

20.0 0.787 |

25.0 0.984 |

|||

| Ağırlık/Weight(kg/m.) | ||||||||||||||||||

| 8 | 200 | 219.1 | 21.2 | 23.8 | 26.4 | 29.5 | 33.1 | 37.1 | 41.6 | 45.6 | 51.6 | |||||||

| 10 | 250 | 273.0 | 26.5 | 29.8 | 33.0 | 36.9 | 41.4 | 46.6 | 52.3 | 57.3 | 64.9 | |||||||

| 12 | 300 | 323.9 |

31.6 |

35.4 | 39.3 |

44.0 |

49.3 | 55.5 | 62.3 | 68.4 | 77.4 | 84.9 | 96.0 | |||||

| 14 | 350 | 355.6 | 34.7 |

39.0 |

43.2 | 48.3 | 54.3 | 61.0 | 68.6 | 75.3 | 85.2 | 93.5 | 106 | |||||

| 16 | 400 | 406.4 | 39.7 | 44.6 | 49.5 | 55.4 | 62.2 | 69.9 | 78.6 | 86.3 | 97.8 | 107 | 121 | |||||

| 18 | 450 | 457.2 | 44.7 | 50.2 | 55.7 | 62.3 |

70.0 |

78.8 | 88.6 | 97.3 | 110 | 121 | 137 | |||||

| 20 | 500 | 508.0 | 49.7 | 55.9 | 62.0 | 69.4 | 77.9 | 87.7 | 98.6 | 108.0 | 123 | 135 | 153 | |||||

| 22 | 550 | 558.8 | 61.5 | 68.3 | 76.4 | 85.9 | 96.6 | 109 | 119 | 135 | 149 | 168 | 191 | 214 | ||||

| 24 | 600 | 609.6 | 74.6 | 83.5 | 93.8 | 106 | 119 | 130 | 148 | 162 | 184 | 209 | 234 | |||||

| 26 | 650 | 660.4 | 80.8 | 90.4 | 102 | 114 | 129 | 141 | 160 | 176 | 200 | 226 | 254 | |||||

| 28 | 700 | 711.2 | 87.1 | 97.4 | 109 | 123 | 139 | 152 | 173 | 190 | 215 | 244 | 274 | |||||

| 30 | 750 | 762.0 | 104 | 117 | 132 | 149 | 163 | 185 | 204 | 231 | 262 | 294 | ||||||

| 32 | 800 | 812.8 | 112 | 125 | 141 | 159 | 175 | 198 | 218 | 247 | 280 | 314 | ||||||

| 34 | 850 | 863.6 | 133 | 150 | 169 | 186 | 211 | 231 | 262 | 298 | 335 | |||||||

| 36 | 900 | 914.4 | 141 | 159 | 179 | 196 | 223 | 245 | 278 | 315 | 354 | |||||||

| 40 | 1000 | 1016.0 | 157 | 177 |

199 |

219 | 248 | 273 | 309 | 351 | 395 | |||||||

| 44 | 1100 | 1118.0 | 219 | 241 | 273 | 300 | 341 | 387 | 435 | |||||||||

| 48 | 1200 | 1219.0 | 239 | 263 | 298 | 328 | 372 | 422 | 474 | |||||||||

| 52 | 1300 | 1321.0 | 259 | 285 | 323 | 355 | 403 | 458 | 515 | |||||||||

| 56 | 1400 | 1422.0 | 279 | 307 | 348 | 383 | 435 | 493 | 555 | |||||||||

| 60 | 1500 | 1524.0 | 373 | 410 | 466 | 529 | 595 | |||||||||||

| 64 | 1600 | 1626.0 | 399 | 438 | 497 | 564 | 635 | 694 | 792 | |||||||||

| 68 | 1700 | 1727.0 | 529 | 600 | 675 | 738 | 842 | |||||||||||

| 72 | 1800 | 1829.0 | 560 | 636 | 715 | 782 | 892 | |||||||||||

| 80 | 2000 | 2032.0 | 623 | 707 | 795 | 869 | 992 | 1237 | ||||||||||

| 88 | 2200 | 2235.0 | 778 | 876 | 957 | 1093 | 1363 | |||||||||||

| 100 | 2500 | 2540.0 | 885 | 996 | 1089 | 1243 | 1551 | |||||||||||

| 120 | 3000 | 3048.0 | 1196 | 1308 | 1493 | 1864 | ||||||||||||

Field Application

- Interior - Exterior Coating Bitumen.

- TS 4356, DIN 30673, BS 4147

- Interior - Exterior Coal-Tar Enamel Coating

- TS 4357, AWWA C-203

- Interior - Exterior Coal-tar epoxy or solvent-free epoxy coating.

- Ts 5140, AWWA c-210, NFA 49709

- External Polyethylene Coating (3 times)

- Ts 5139, DIN 30670, DIN 30672, NFA 49710, UNI 9099

- Internal Cement Mortar or Cement Mortar Coating Additive

- TS 8590, AWWA c-205, DIN 2614, BS 534

- Fusion Bonded (GSS) Epoxy Coating

- AWWA c-213, API RP 5L7

- Polypropylene Coating

- DIN 30678, NFA 49711

- Polyurethane Coating

- AWWA c-222, BS EN 10290

Production Type

Production Range: 219,1 mm - 3750 mm

Wall Thickness: 4 mm - 25 mm

Pipe Length: 6 m - 30 m

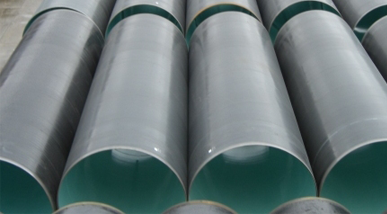

Pipe İsolations

The following types of insulation is applied in order to protect against corrosion of pipes:

Interior - Exterior Coal-Tar Enamel Coating

TS 4357, AWWA C-203

Interior - Exterior Coal-tar epoxy or solvent-free epoxy coating.

TS 5140, AWWA c-210, NFA 49709

External Polyethylene Coating (3 times)

Ts 5139, DIN 30670, DIN 30672, NFA 49710, UNI 9099

Internal Cement Mortar or Cement Mortar Coating Additive

TS 8590, AWWA c-205, DIN 2614, BS 534

Fusion Bonded (GSS) Epoxy Coating

AWWA c-213, API RP 5L7

Polypropylene Coating

DIN 30678, NFA 49711

Polyurethane Coating

AWWA c-222, BS EN 10290