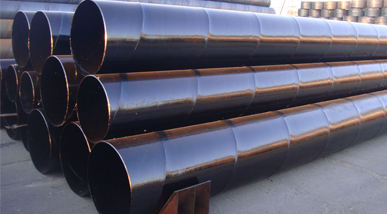

ERW Longitudinally Welded

| BOYUNA KAYNAKLI ( ERW ) ÇELİK BORU ÜRETİM ARALIĞI TABLOSU | ||||||||||||||||||||

| LONGITUDINALLY HIGH-FREQUENCY WELDED STEEL PIPES ( HFW ) PRODUCTION RANGE TABLE | ||||||||||||||||||||

|

Nominal Çap

Nominal Diametler inch mm. |

Standart Dış Çap

Standart O.D

mm.

|

Standart Et Kalınlığı

Standard

W.T.

inch mm.

|

Ağırlık

Weight

kg/m

|

Et Kalınlıkları/W.T.(mm/inch) |

||||||||||||||||

|

2.0 0.078 |

2.6 0.102 |

2.9 0.114 |

3.2 0.125 |

3.6 0.141 |

4.0 0.160 |

4.5 0.176 |

5.0 0.192 |

5.6 0.219 |

6.3 0.250 |

7.1 0.281 |

8.0 0.312 |

8.8 0.344 |

10.0 0.394 |

12.5 0.492 |

||||||

| Ağırlık/Weight(kg/m.) | ||||||||||||||||||||

| 2 | 50 | 60.3 | 0.090 | 2.3 | 3.29 | 2.88 | 3.70 | 4.11 | 4.51 | 05.03 | 5.55 | 6.19 | 6.82 | |||||||

| 2.5 | 65 | 76.1 | 0.102 | 2.6 | 4.71 | 3.65 | 4.71 | 5.24 | 5.75 | 6.44 | 7.11 | 7.95 | 8.77 | |||||||

| 3 | 80 | 88.9 | 0.114 | 2.9 | 6.15 | 4.29 | 5.53 | 6.15 | 6.76 | 7.57 | 8.38 | 9.37 | 10.3 | 11.5 | ||||||

| 4 | 100 | 114.3 | 0.125 | 3.2 | 8.77 | 5.54 | 7.16 | 7.97 | 8.77 | 9.83 | 10.9 | 12.2 | 13.5 | 15.0 | 16.2 | |||||

| 5 | 125 | 139.7 | 0.141 | 3.6 | 12.1 | 8.79 | 9.78 | 10.8 | 12.1 | 13.4 | 15.0 | 16.5 | 18.6 | 20.7 | 23.2 | |||||

| 5.5 | 125 | 141.3 | 0.141 | 3.6 | 12.2 | 8.89 | 9.90 | 10.9 | 12.2 | 13.5 | 15.2 | 16.8 | 18.7 | 21.0 | 23.5 | |||||

| 6 | 150 | 159 | 0.160 | 4.0 | 15.3 | 11.2 | 12.3 | 13.5 | 15.3 | 17.1 | 19.0 | 21.2 | 23.7 | 26.6 | 29.8 | |||||

| 6.5 | 175 | 165.1 | 0.160 | 4.0 | 16.0 | 11.7 | 12.9 | 14.4 | 16.0 | 17.8 | 19.7 | 21.9 | 24.8 | 27.7 | 30.9 | |||||

| 6.5 | 175 | 168.3 | 0.160 | 4.0 | 16.2 | 13.0 | 14.6 | 16.2 | 18.2 | 20.1 | 22.5 | 25.2 | 28.2 | 31.6 | ||||||

| 8 | 200 | 219.1 | 0.176 | 4.5 | 23.6 | 17.0 | 19.1 | 21.2 | 23.6 | 26.4 | 29.5 | 33.1 | 37.1 | 41.8 | 45.6 | 51.6 | 63.7 | |||

| 10 | 250 | 273.0 | 0.192 | 5.0 | 33.0 | 23.9 | 26.5 | 29.6 | 33.0 | 36.9 | 41.4 | 46.6 | 52.3 | 53.7 | 64.9 | 80.3 | ||||

| 12 | 300 | 323.9 | 0.219 | 5.6 | 44.0 | 31.6 | 35.4 | 39.3 | 44.0 | 49.3 | 55.5 | 62.3 | 68.4 | 77.4 | 96.0 | |||||

| 14 | 350 | 355.6 | 0.219 | 5.6 | 48.3 | 34.7 | 39.0 | 43.2 | 48.3 | 54.3 | 61.0 | 68.6 | 75.3 | 85.2 | 106 | |||||

| 16 | 400 | 406.4 | 0.250 | 6.3 | 62.2 | 44.6 | 49.4 | 55.4 | 62.2 | 69.9 | 78.6 | 86.3 | 97.8 | 121 | ||||||

| 17 | 425 | 426.0 | 0.250 | 6.3 | 65.2 | 46.8 | 51.9 | 58.0 | 65.2 | 73.3 | 82.4 | 90.5 | 103 | 127 | ||||||

Field Application

- Interior - Exterior Coating Bitumen.

- TS 4356, DIN 30673, BS 4147

- Interior - Exterior Coal-Tar Enamel Coating

- TS 4357, AWWA C-203

- Interior - Exterior Coal-tar epoxy or solvent-free epoxy coating.

- Ts 5140, AWWA c-210, NFA 49709

- External Polyethylene Coating (3 times)

- Ts 5139, DIN 30670, DIN 30672, NFA 49710, UNI 9099

- Internal Cement Mortar or Cement Mortar Coating Additive

- TS 8590, AWWA c-205, DIN 2614, BS 534

- Fusion Bonded (GSS) Epoxy Coating

- AWWA c-213, API RP 5L7

- Polypropylene Coating

- DIN 30678, NFA 49711

- Polyurethane Coating

- AWWA c-222, BS EN 10290

Production Type

Outside Diameter: 2"-17" (60,2-426,0 mm.)

Wall Thickness: 2 - 14 mm

Boy: 6-16 m.

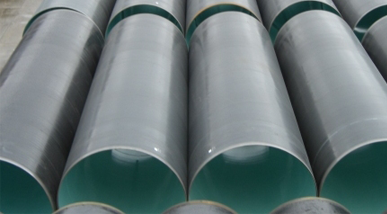

Pipe Isolations

The following types of insulation is applied in order to protect against corrosion of pipes:

Interior - Exterior Coal-Tar Enamel Coating

TS 4357, AWWA C-203

Interior - Exterior Coal-tar epoxy or solvent-free epoxy coating.

TS 5140, AWWA c-210, NFA 49709

External Polyethylene Coating (3 times)

Ts 5139, DIN 30670, DIN 30672, NFA 49710, UNI 9099

Fusion Bonded (GSS) Epoxy Coating

AWWA c-213, API RP 5L7

Polypropylene Coating

DIN 30678, NFA 49711

Polyurethane Coating

AWWA c-222, BS EN 10290